REMANUFACTURING

Our Equipment & Capabilities

At Prime Forest Products, we combine decades of industry expertise with advanced machinery to deliver consistent, high-quality softwood products. Below is a look at the state-of-the-art equipment we use in our remanufacturing operations.

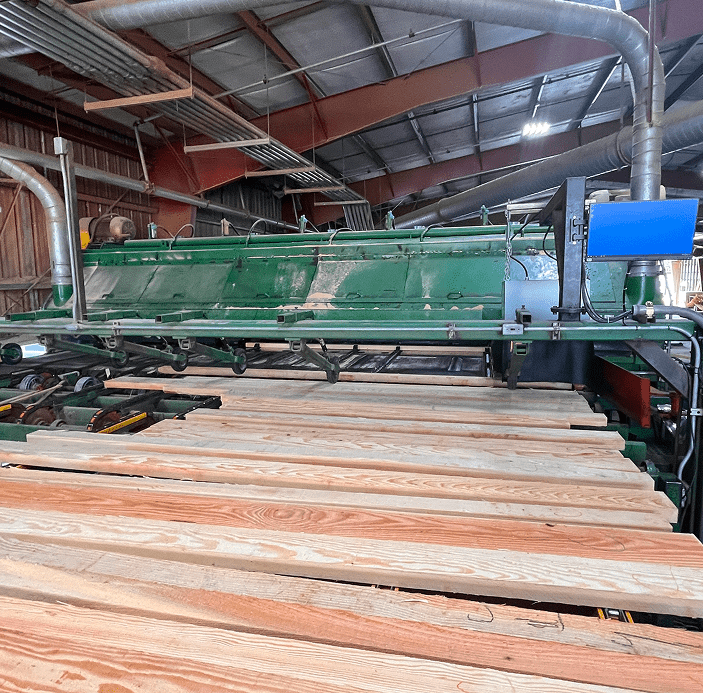

Baker resaws

Our Baker resaws are designed for precision and versatility. These machines allow us to cut boards into thinner components or custom dimensions with minimal waste. Perfect for specialty orders, our resaws help us meet a wide variety of customer specs quickly and efficiently.Lumber Planer and Sort Chain

Our high-speed planer ensures dimensional accuracy and a smooth finish for every board. After planing, boards are conveyed to the sort chain where they are graded, sorted by size and quality, then routed for the next stage of processing.

Leadermac L6, L9, and L12 Moulders

We operate a fleet of advanced Leadermac moulders capable of producing a wide range of profiles. From tongue-and-groove to bevel siding and custom patterns, these machines can handle the following: L6 – Light-duty, precision profiling, L9 – Medium production with flexible set-ups, L12 – High-output runs with complex multi-knife configurations. No matter the profile, our moulders ensure clean, consistent finishes.

350 Optimizer

Our 350 Optimizer uses laser scanning and computer vision to identify defects and determine the best cut strategy in real time. This allows us to maximize usable fiber, reduce waste, and improve yield per board. It’s a key part of how we add value and efficiency to every piece of wood.

Sticker Stacker

Efficient drying starts with proper stacking. Our sticker stacker automates the process of placing spacer sticks between boards, allowing for optimal air flow and even drying in our kilns. It’s a key part of maintaining board integrity and reducing drying defects like warp.

Dry Kilns

We operate computer-controlled dry kilns to bring lumber to its ideal moisture content, ensuring stability and quality. Prime Forest Remanufacturing has two double track and two single track conditioning kilns that are HT certified with a drying capacity of 400 MBF. Our lumber is dried to 12% or less moisture content and every load is tested for case hardening.

Cutline

Our custom cutline is manually operated using human eyes to ensure that every board is cut to length. Each piece is then checked for moisture content and double-checked for grade before being packaged for shipment. The benefits are precision cuts, clean end trims, and consistent product dimensions.

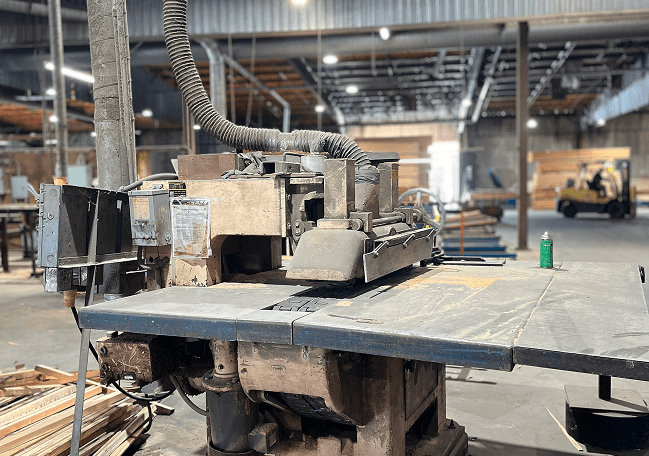

Ripsaw

The ripsaw enables us to cut boards along their length, turning wide lumber into narrower strips. Whether for panel components or custom rip sizes, our ripsaw setup delivers clean edges with precision accuracy.

Need Something Custom?

Our team thrives on specialty work. From custom profiles to unique dimensions, we’re ready to collaborate on your next project. Contact us today to learn more about what our equipment—and our team—can do for you.